Phone:

+86 13553744936

jessieweldomachine@163.com

Breaking Down the Cost of Making Enamel Pins in 2025/2026

Enamel pins have become an iconic accessory for fans, collectors, and businesses alike. However, the cost of making these pins can vary greatly depending on a number of factors. In this article, we provide a comprehensive guide on the costs involved in making enamel pins in 2025 and 2026. From design to production, we will explore the key elements that influence the price, including the role of specialized machinery like the uncle sam enamel pin badge filling machine and animal enamel pin badge filling machine.

1. Design Process and Initial Costs

The design of your enamel pin plays a significant role in the overall cost. Simple, less intricate designs can cost as little as $50 to $100, while complex designs may run upwards of $500 or more. Additionally, if your design requires custom machines like the American pride enamel pin filling machine or LGBTQ+ pride pin filling machine, the costs will naturally rise. These machines allow for specialized designs that are unique to certain demographics or causes.

2. Material Selection

The materials you select will have a direct impact on the cost. Hard enamel pins are usually more expensive than soft enamel pins due to the extra processes involved in finishing them. Additionally, for pins that involve intricate detailing, such as those produced using the Limited edition Disney enamel pin badge filling machine, special finishes and color variants may also affect the cost.

3. Production Scale and Volume

One of the largest factors in determining the cost of enamel pins is the production scale. Small runs of pins are generally more expensive to produce than larger runs due to the higher setup costs. If you plan to produce a limited edition set, using the Limited edition Disney enamel pin badge filling machine, you may incur higher per-unit costs initially. However, larger orders often see a lower cost per unit thanks to economies of scale.

4. The Role of Machinery in Production

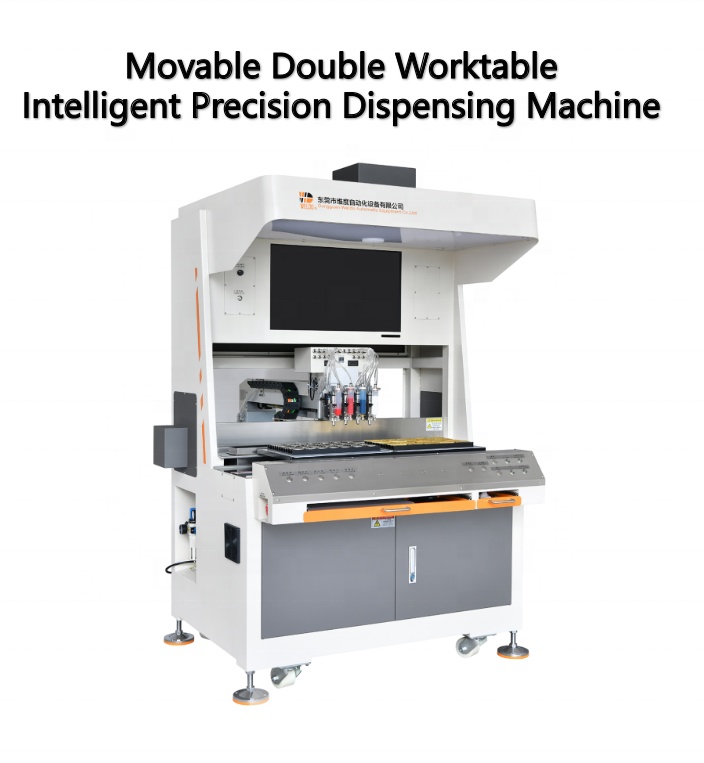

Machines like the uncle sam enamel pin badge filling machine and animal enamel pin badge filling machine are designed to streamline production and improve efficiency. These machines can significantly reduce production time, which ultimately lowers the cost per unit. However, the upfront investment for these machines can range anywhere from $5,000 to $20,000. For businesses looking to scale up production, investing in these machines can be cost-effective in the long run.

5. Packaging and Delivery

Although often overlooked, packaging is another critical factor that contributes to the overall cost of enamel pin production. Custom packaging that ensures the pins are well-protected during transit can be more expensive than basic packaging. Additionally, shipping fees, which can vary depending on the size of the order and location, should be factored into your overall cost.

Conclusion

The cost of making enamel pins in 2025 and 2026 is influenced by several key factors, including design complexity, materials, production scale, and the use of specialized machines like the uncle sam enamel pin badge filling machine, animal enamel pin badge filling machine, and other machines dedicated to specific types of pins, such as the LGBTQ+ pride pin filling machine or the Limited edition Disney enamel pin badge filling machine. By understanding these variables, businesses and creators can make more informed decisions about their enamel pin production.

READ MORE:

- Market Growth of Colorful Metal Tags: An Overview

- The Expanding Market for Custom Engraved Metal Tags

- How Technology is Shaping the Metal Tags Market

- Growth and Trends in the Metal Tags Market: Key Factors Driving Expansion

- How Much Does It Cost To Make Enamel Pins in 2025/2026? The Full Guide And Breakdown!

- Understanding the Size of the Metal Tags Market

- How Much Does It Cost To Make Enamel Pins in 2025/2026? The Full Guide And Breakdown!

- Revolutionizing Custom Metal Tag Production with Advanced Paint Filling Machines

- Enhancing Custom Metal Tag Production with Advanced Paint Filling Machines