Phone:

+86 13553744936

jessieweldomachine@163.com

Understanding the Costs Behind Making Enamel Pins in 2025/2026

As enamel pins continue to grow in popularity, creators and businesses are increasingly looking into how much it costs to produce these coveted items. In this guide, we will provide an overview of the key factors that contribute to the cost of making enamel pins in 2025 and 2026, including design complexity, production volume, and the machinery used, such as the Uncle Sam enamel pin badge filling machine and the animal enamel pin badge filling machine.

1. Design Complexity and Customization

The cost of creating an enamel pin starts with the design process. Simple designs with fewer details are less expensive to produce, while complex and intricate designs can be much costlier. If you are creating special edition pins for a specific cause, such as using the American pride enamel pin filling machine for a national holiday collection or the LGBTQ+ pride pin filling machine for a pride event, the design and production costs may increase due to additional customization.

2. Materials and Finishes

Material choice plays a significant role in the overall price of enamel pin production. Hard enamel pins, for example, are more expensive than soft enamel pins due to the extra finishing steps required. When using specialized machines, like the Limited edition Disney enamel pin badge filling machine, the cost of materials and special finishes can rise due to the added complexity of the manufacturing process.

3. Production Scale and Minimum Order Quantities

The scale of production is another factor that directly impacts cost. Small runs of enamel pins tend to be more expensive per unit because of the setup and labor involved. On the other hand, larger orders benefit from economies of scale, reducing the cost per unit. For instance, if you are using the Uncle Sam enamel pin badge filling machine or the animal enamel pin badge filling machine for mass production, the cost per unit becomes lower as more pins are produced at once.

4. Machinery Investment

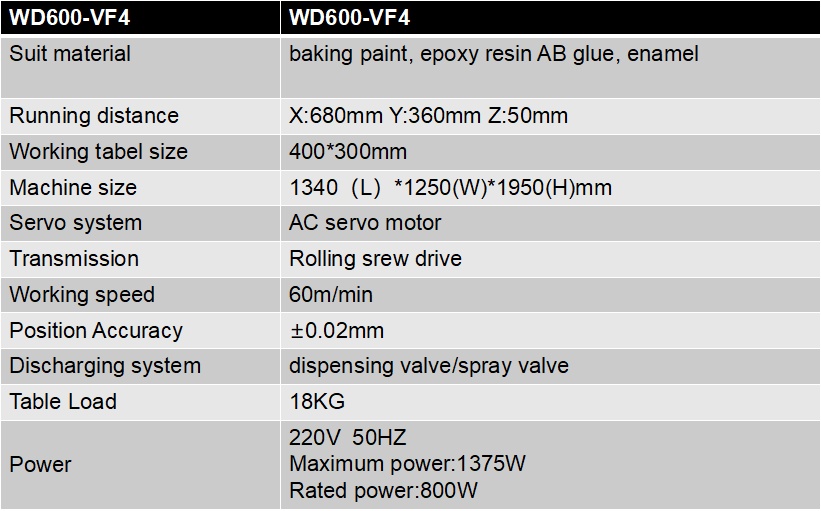

Specialized machinery plays a crucial role in enamel pin production, allowing businesses to produce large quantities with speed and accuracy. Machines like the Uncle Sam enamel pin badge filling machine and animal enamel pin badge filling machine are designed to streamline the manufacturing process and reduce labor costs. However, these machines are a significant investment, with prices ranging from $5,000 to $20,000. Although the upfront costs can be high, they are often justified by the long-term savings in production costs.

5. Packaging and Shipping

Packaging is another cost that is sometimes overlooked in enamel pin production. Custom packaging to protect the pins during shipping adds to the overall cost, especially if you are offering premium packaging for limited edition pins, such as those produced with the Limited edition Disney enamel pin badge filling machine. Shipping costs can also add up, depending on the size and location of the order.

Conclusion

In conclusion, the cost of making enamel pins in 2025/2026 depends on various factors, including design, materials, production scale, and the machinery involved. Machines like the Uncle Sam enamel pin badge filling machine and the animal enamel pin badge filling machine are essential tools for businesses looking to scale production efficiently. By understanding these factors, businesses can better estimate the cost of producing enamel pins and plan accordingly for their projects.

READ MORE:

- The Booming Metal Tags Market and Customization Trends

- The Rapid Expansion of the Metal Tags Market

- Understanding the Cost of Enamel Pin Production in 2025/2026

- The Cost of Producing Enamel Pins in 2025/2026: A Breakdown

- The Growth of the Metal Tags Market: Key Drivers and Trends

- Breaking Down the Cost of Enamel Pin Production in 2025/2026

- The Complete Guide to Enamel Pin Production Costs in 2025/2026

- The Full Breakdown of Enamel Pin Production Costs in 2025/2026

- Understanding the Cost of Making Enamel Pins in 2025/2026